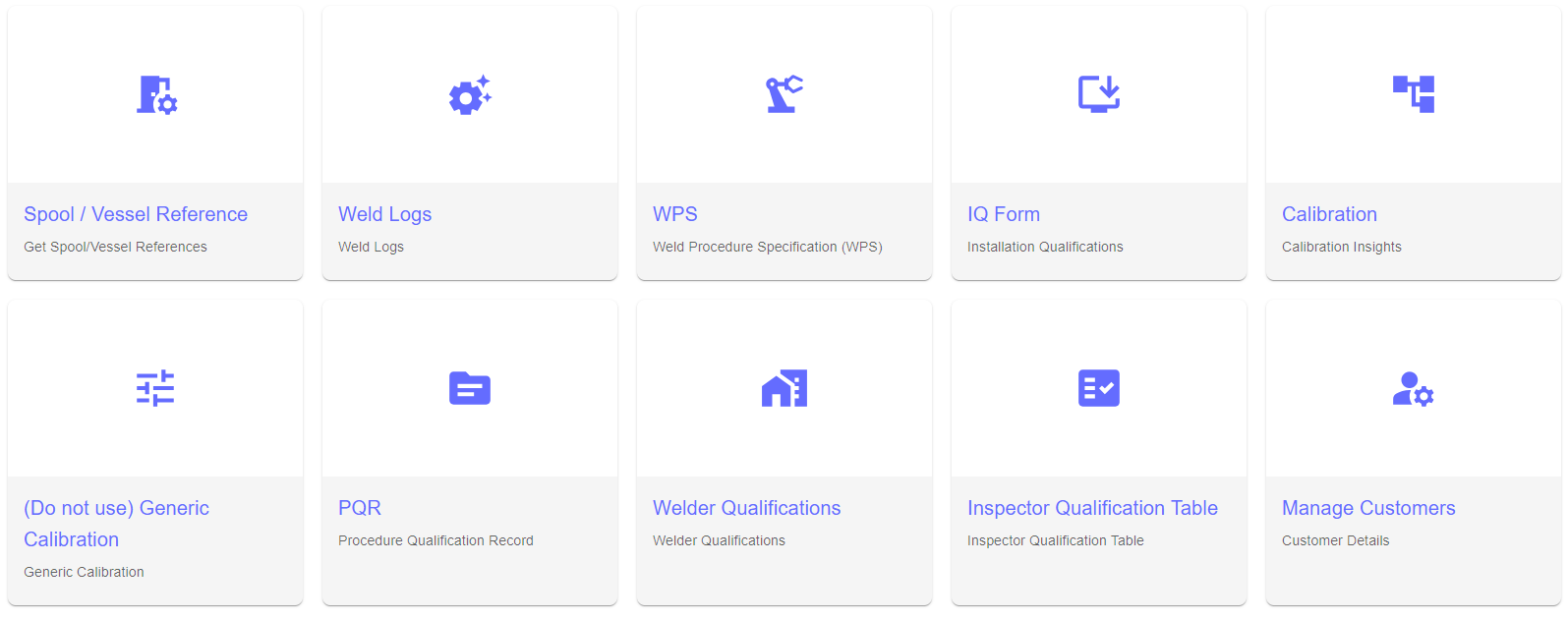

Welcome to the Q-Weld homepage, your centralised hub for managing all your welding operations with ease and efficiency. Here, you will find an organised display of all available tables, each designed to provide crucial insights and functionalities. From weld logs and traceability records to interactive dashboards, every table is intuitively arranged for quick access and real-time updates. Navigate seamlessly through comprehensive data sets tailored to meet the specific needs of the pharmaceutical welding industry. With Q-Weld, all the information you need is at your fingertips, empowering you to make informed decisions and maintain the highest standards of quality and compliance.

Q-Weld not only streamlines weld logging and tracing but also provides complete control over your staff and stock. With its comprehensive tracking system, you can monitor the performance and productivity of your welding team in real-time, ensuring that each task is executed with precision and accountability. Additionally, Q-Weld offers robust inventory management features, allowing you to keep accurate records of welding materials and equipment. This dual capability ensures optimal resource allocation, reduces waste, and enhances overall operational efficiency, giving you full oversight and control over your welding processes.

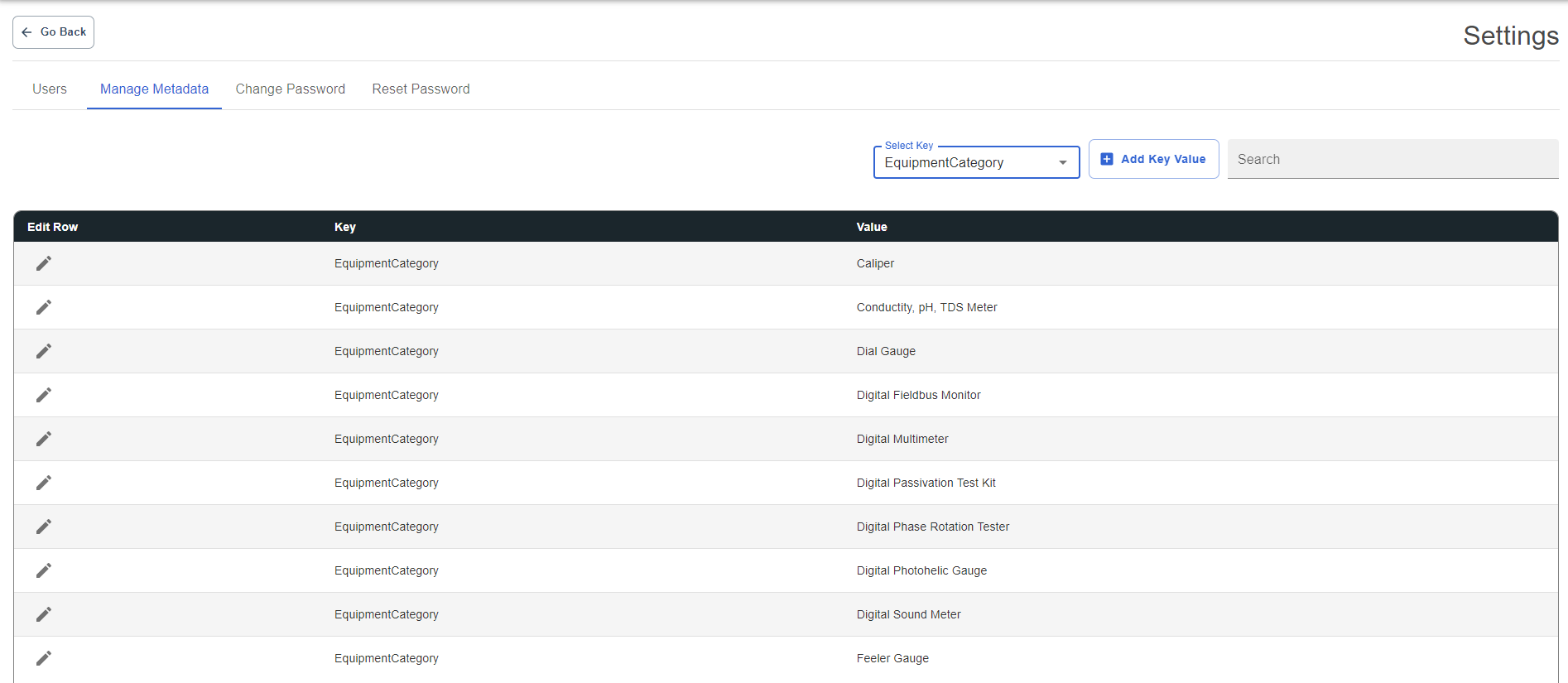

Q-Weld offers you exceptional autonomy by allowing you to manipulate all metadata directly within the system. This feature provides you with complete control over your data management and system configurations, eliminating the need to contact support for routine adjustments. Whether you’re updating records, adjusting parameters, or managing data fields, Q-Weld’s intuitive interface empowers you to make changes effortlessly. With this level of control at your fingertips, you can ensure that the system perfectly aligns with your specific operational needs and standards, streamlining your workflow and enhancing overall efficiency.